冷热混料机

We provide heating/cooling mixing system and turbo mixing machines for specific bulk solid process applications, including but not limited to:

我们为特殊固体散料混合工艺提供多种冷热混合及高速涡流混合机型,包括且不限于:

Heating & Cooling Mixers Conbination System 冷热混合机组

|

|

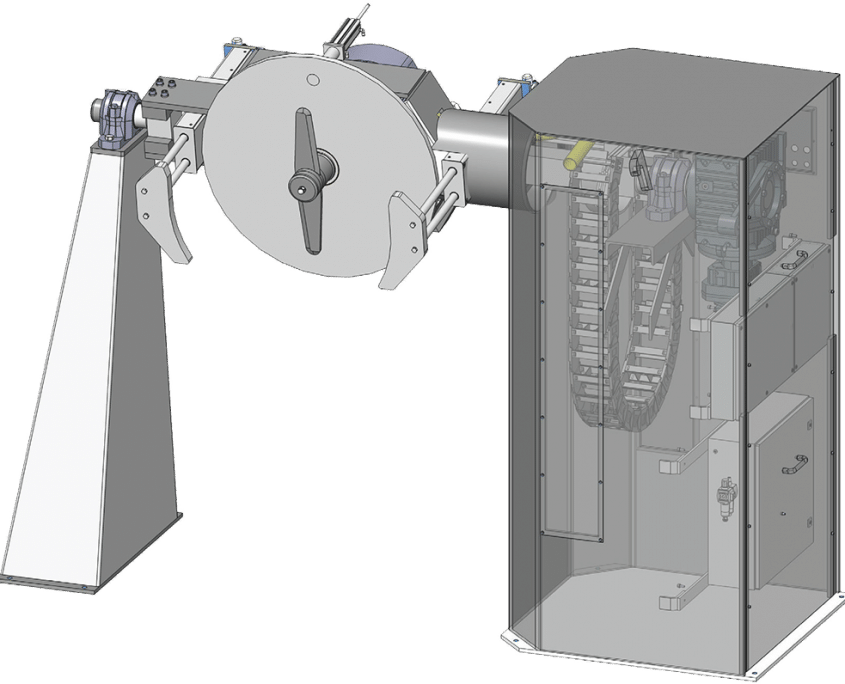

Combined heating/cooling mixers are the optimum solution for complex mixing challenges. The systems are characterized by their outstanding product preparation in the heating phase and high-efficiency cooling performance. The horizontal and vertical heating/cooling mixers are designed for high-volume throughput, rapid processing and short cleaning times.

Combined heating/cooling mixers are mainly used for:

- RIGID AND SOFT PVC MIXING

- MIXING RIGID OR PLASTICIZED PVC

- METALIC BONDING

There are two cominations available:

- Heating Mixer With Horizontal Cooling Mixer- Heating Mixer With Vertical Cooling Mixer

|

|

|

Turbo Mixers 涡流混合机

|

|

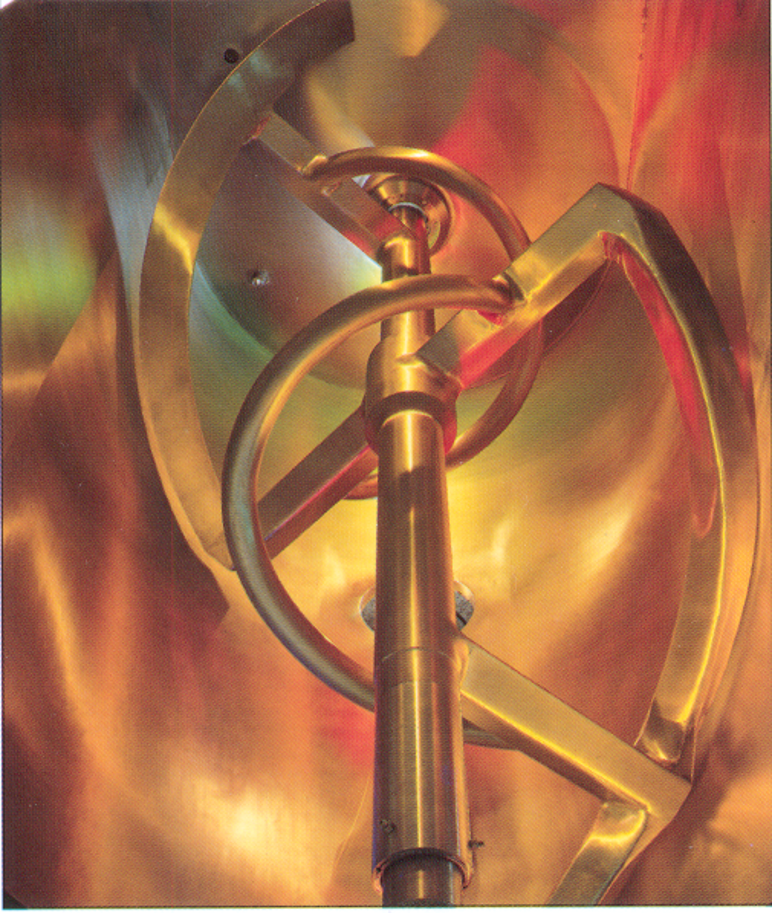

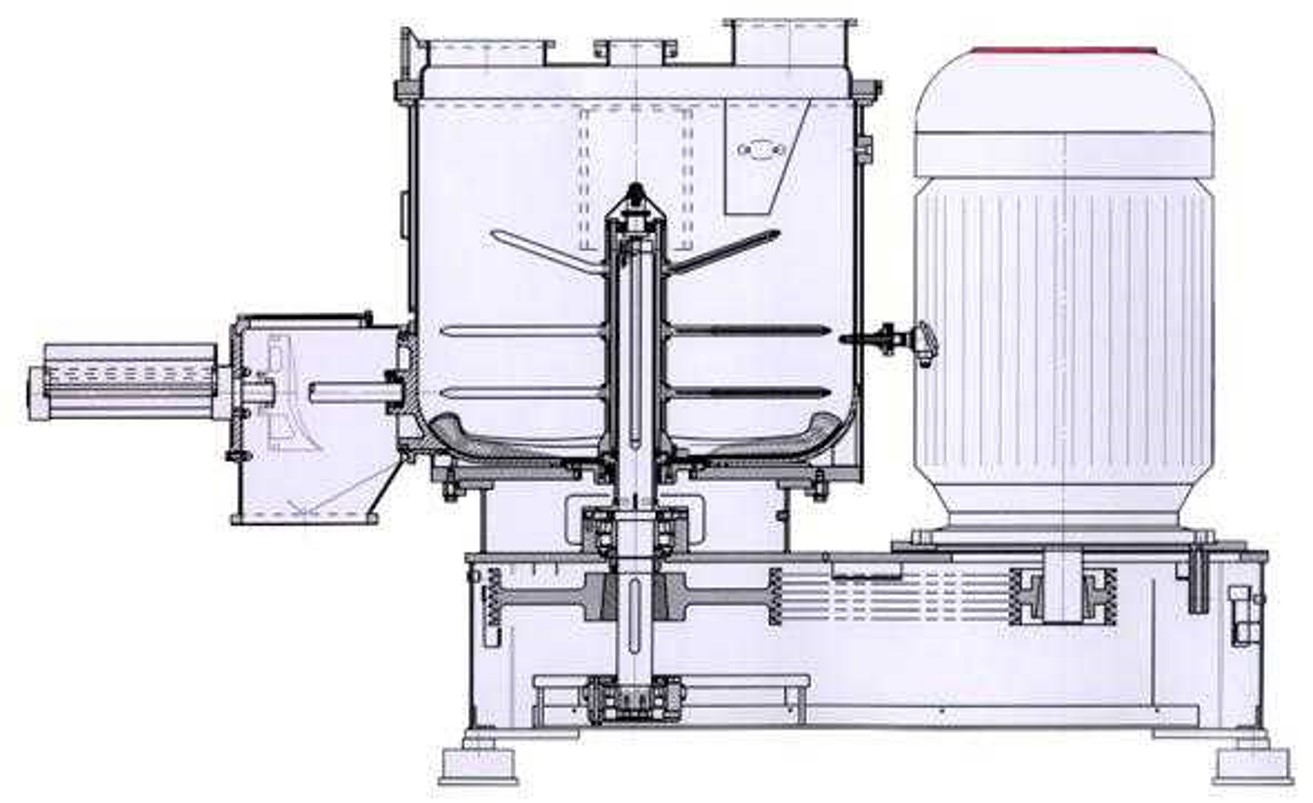

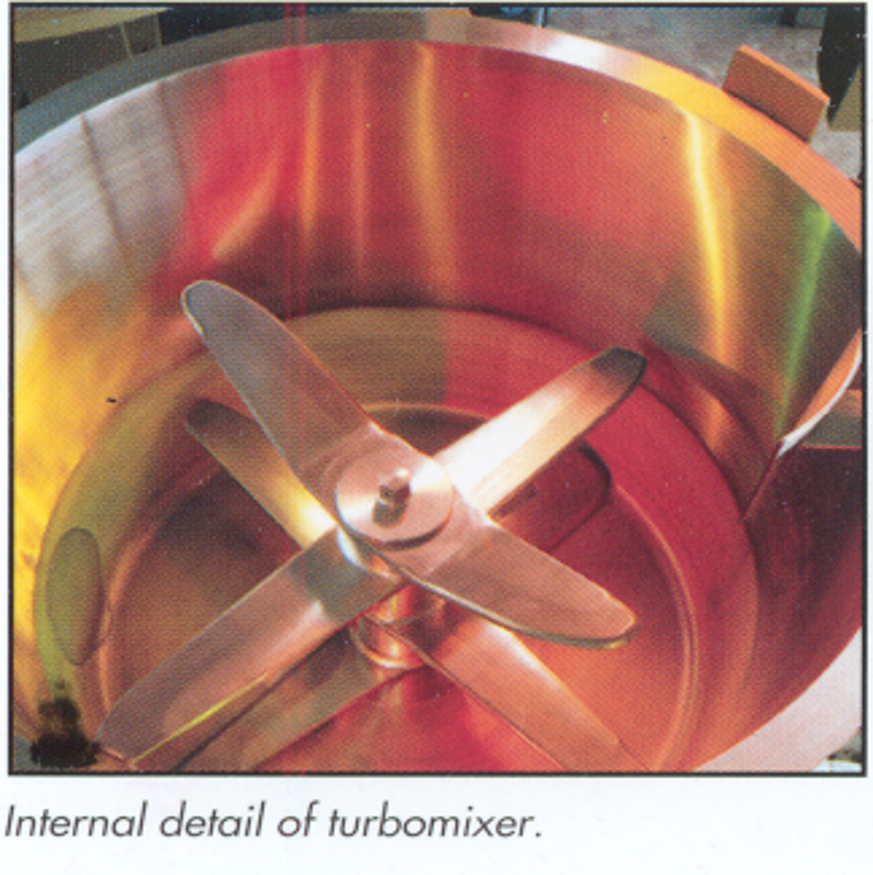

Turbomixers have shown themselves to be very effective in the thermoplastic transformation industry. When a high quality of material and a high hourly production rate are required, turbomixers are the ideal solution. These machines are mainly used to produce PVC DRY-BLEND, either rigid or plasticized, from polymers in suspension, emulsion or mass.

These machines are also used for densification or heat agglomeration of other resins such as ABS, POM, PE and PP and for drying, hot or cold distribution of pigments and moistening.

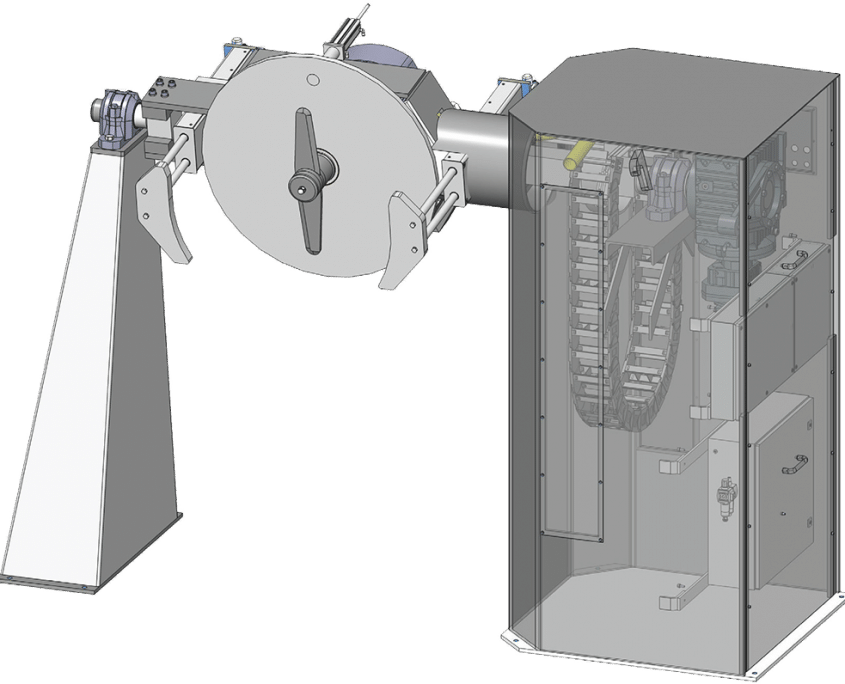

Container Mixers 容器式混合机

|

|

Container mixers are the ideal alternative to conventional turbomixers when production conditions require a high degree of versatility and a wide range of different products to be mixed with the same machine, for example colorized masterbatches and metal powder coatings. Thanks to the machine's special construction dividing in into two separate units, mixer and storage hopper, clenning time is reduced to a minimum and theretore also the rísk of contamination in passing from one type of production to another. Mix storage and transportation are aided by directly using the same containers that can easily be inserted in a batching system.

Various Mixer Features 多种配置与特征

新加坡

TEL 0065 6321 9157

FAX 0065 6324 1513

中国北京

TEL 0086 10 5977 1616

FAX 0086 10 5977 1515

![]() info@compassbulk.com

info@compassbulk.com