粒度检测仪

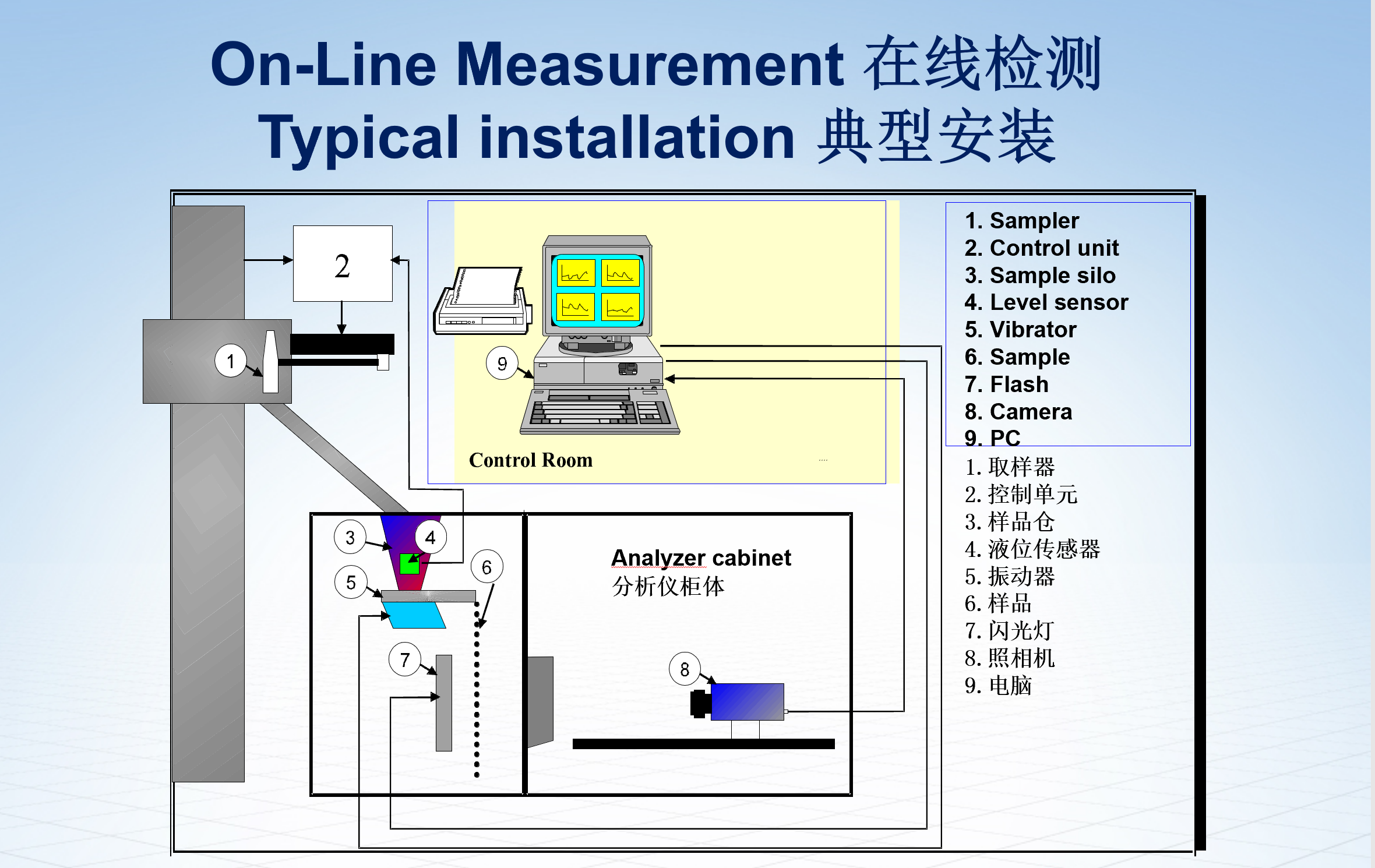

我们提供在线粒度检测仪,配合粉粒体生产前端及后端工艺控制,可以帮助您实现国际顶级质量标准的粉粒体颗粒粒度生产工艺控制:

A,激光粒度检测仪

B,三维成像粒度检测仪

在线粒度检测与分析,是为了:

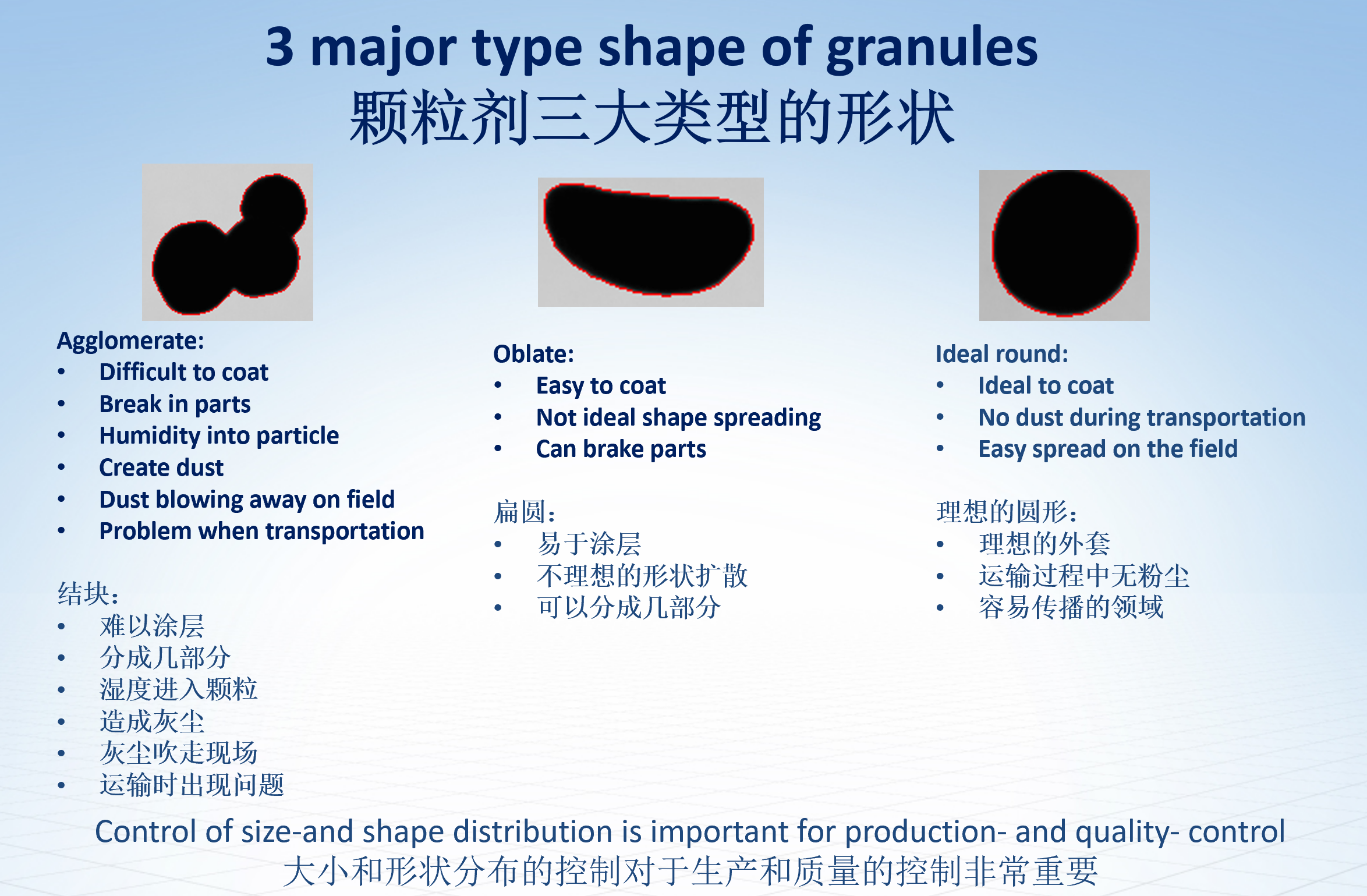

- Granulation performance 造粒的性能与表现

- Optimal levels of recycle (oversize, undersize) 回收的最优量(过大/过小颗粒)

- Crushing performance 破碎的性能与表现

- Ensure optimal load on equipment 确保设备的负荷优化

- Safety of operators 操作人员的安全

- Coating operation efficiency 涂覆作业的效率

- Certifiable final product: size and shape 可认证的最终产品:大小和形状

- Significant revenue and cost savings opportunities 显著收入与成本节能潜力

Benefits of On-Line Particle Image Analysis 在线颗粒图像分析的优势

Significantly increased revenue 收益显著增加

§ Production process producing more on spec product

§ 生产过程生产更多符合规格的产品

§ Optimum level of recycles for maximum factory output

§ 最优化再循环物的水平达到最大工厂产量

§ Immediate response to issues = increased process uptime

§ 对生产问题立即作出反应=提高正常运行过程的时间

Improved Quality &/or Productivity 提高质量和/或生产效率

§ Real time information reduces fluctuations

§ 实时信息,减少波动

§ Automatic sampling is person independent sampling

§ 自动取样,与采样人员无关

§ Real-time information is the same to all shift operators

§ 实时信息对所有换挡操作是一致

Faster start-up 更快速的启动

§ Minimizes surging during start-up 最大程度降低启动过程中涌动

§ Faster to On-spec. production 更快速平衡至生产合规格产品

Less downtime 减少停产时间

§ Respond quickly to variations in granulation 快速响应造粒变动

§ Shorter response time for process adjustments 进行工艺调整后更短的响应时间

Avoids control operator error 避免控制操作员之失误

§ Self teaching of operators 操作员的自行教导

新加坡

TEL 0065 6321 9157

FAX 0065 6324 1513

中国北京

TEL 0086 10 5977 1616

FAX 0086 10 5977 1515

![]() info@compassbulk.com

info@compassbulk.com